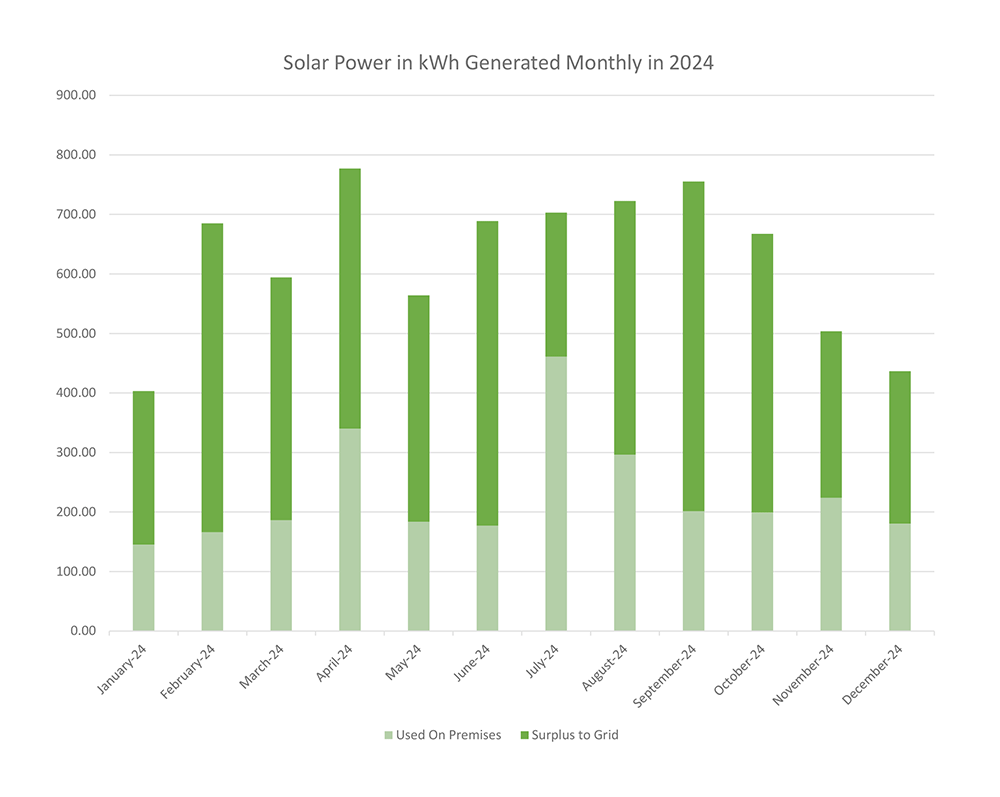

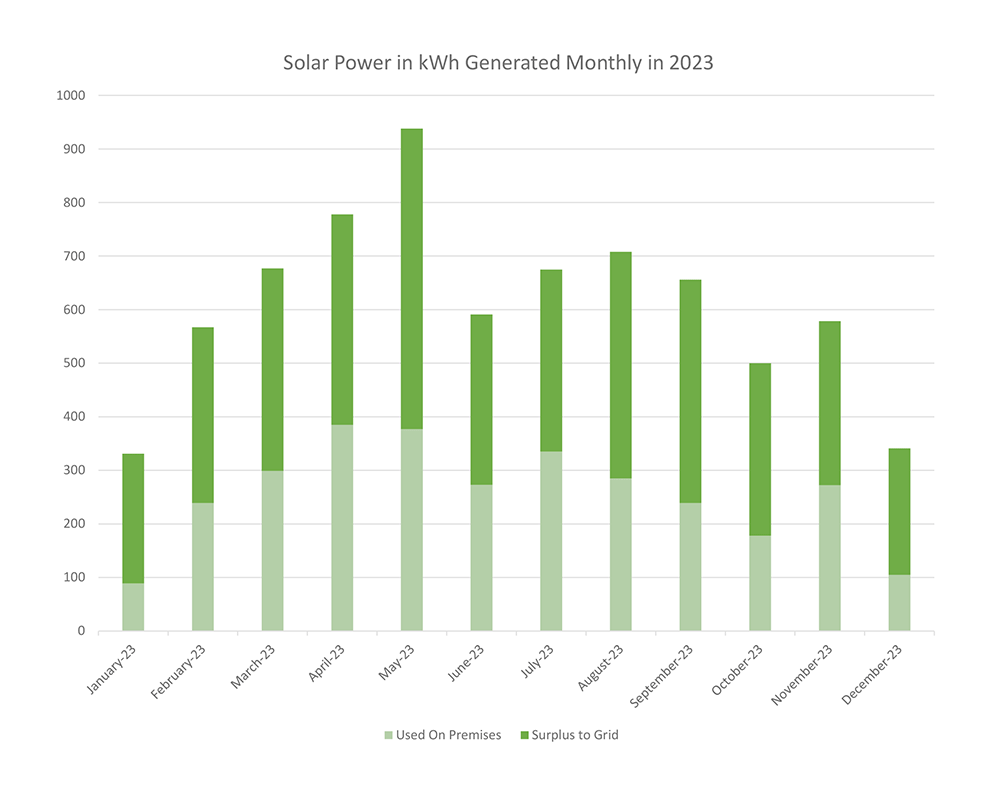

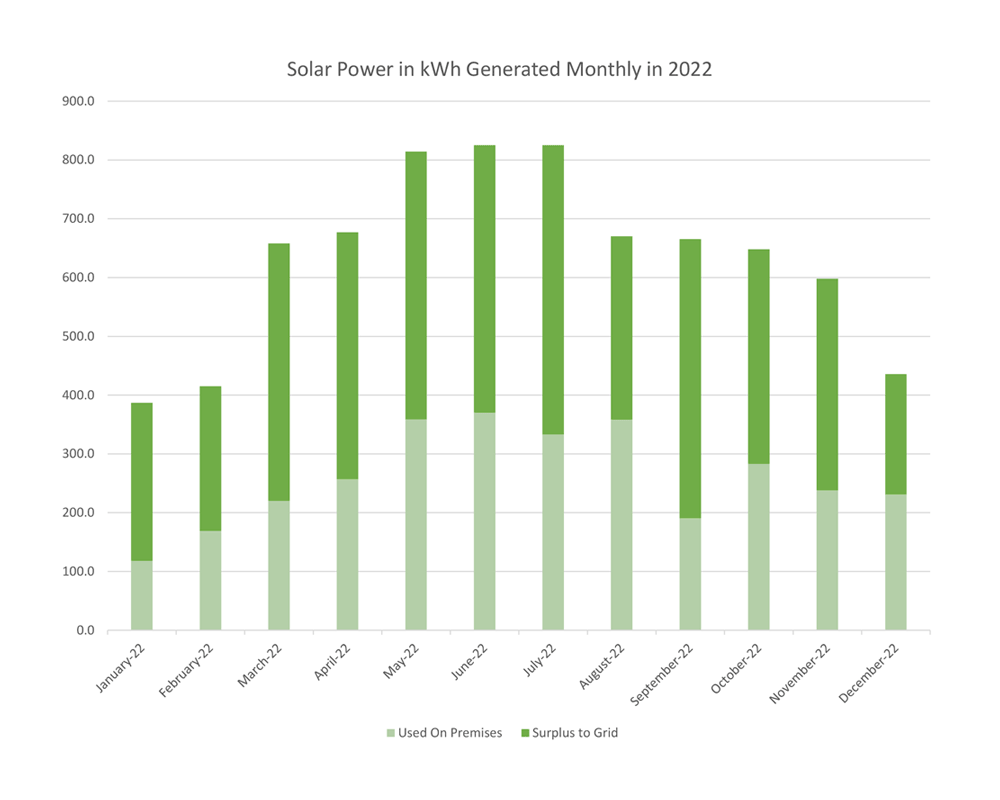

In 2024 we generated a grand total of 7,501.23 kWh of electricity–more than last year but not quite as much as 2022, even with the additional string of panels. Shows how big a factor weather is in productivity.

We used 2,761 kWh running the house and charging our EV, significantly less than last year, while 4,740 kWh went to the grid. April was the biggest generating month, when the system cranked out 777 kWh.

Surprise, surprise, electricity rates rose again in 2024, peaking at a whopping $0.27/kWh. Supply prices continue to slowly decline, but Central Maine Power is now getting $0.12/kWh for delivery, nearly as much as the supply cost. Crazy.

Our clean power production saved approximately 17,000 lbs. of carbon emissions over the past year.

After 7 years we’ve earned back $9,442.25 or 59% of the original investment. As electric rates continue climbing to unheard of levels, we should recoup the cost of the system in the next 3-4 years.